When it comes to strength training, the barbell is a staple piece of equipment.

But have you ever wondered about the different types of coatings on barbells and what they do?

In this guide, we’ll delve into the world of barbell coatings and explore their purpose, benefits, and how to choose the right one for your needs.

On This Page

Understanding Barbell Coatings

Barbell coatings, or finishes, are applied to barbell shafts to protect them from environmental factors like moisture and air that can cause rust and corrosion.

They also provide a certain level of texture and grip, which can enhance your lifting experience.

The type of barbell finish can significantly impact its performance and longevity.

For instance, some barbell coatings offer excellent oxidation resistance, making them ideal for humid environments or gyms without climate control.

Other coatings might prioritize the feel and grip of the bar, which can be crucial for lifts where hand placement and grip are key.

When it comes to maintenance, some barbell coatings require more care than others.

A bare steel bar might need regular cleaning to prevent rust, while a cerakote barbell might require less frequent maintenance.

You can learn more about this in our article on cleaning your barbell.

Factors to Consider When Choosing a Barbell Coating

When choosing a barbell, it’s important to consider the type of barbell finish that suits your needs.

This will depend on several factors, including your budget, the climate of your gym, and your personal preferences for feel and grip.

My barbell buying guide can provide more detailed information to help you make an informed decision.

Types of Barbell Coatings

When it comes to barbell coatings, there are several options to consider.

Each type of coating offers unique characteristics and benefits that can enhance your lifting experience.

Understanding the different types of barbell coatings can help you make an informed decision when selecting the right one for your needs.

Let’s explore some of the most popular types:

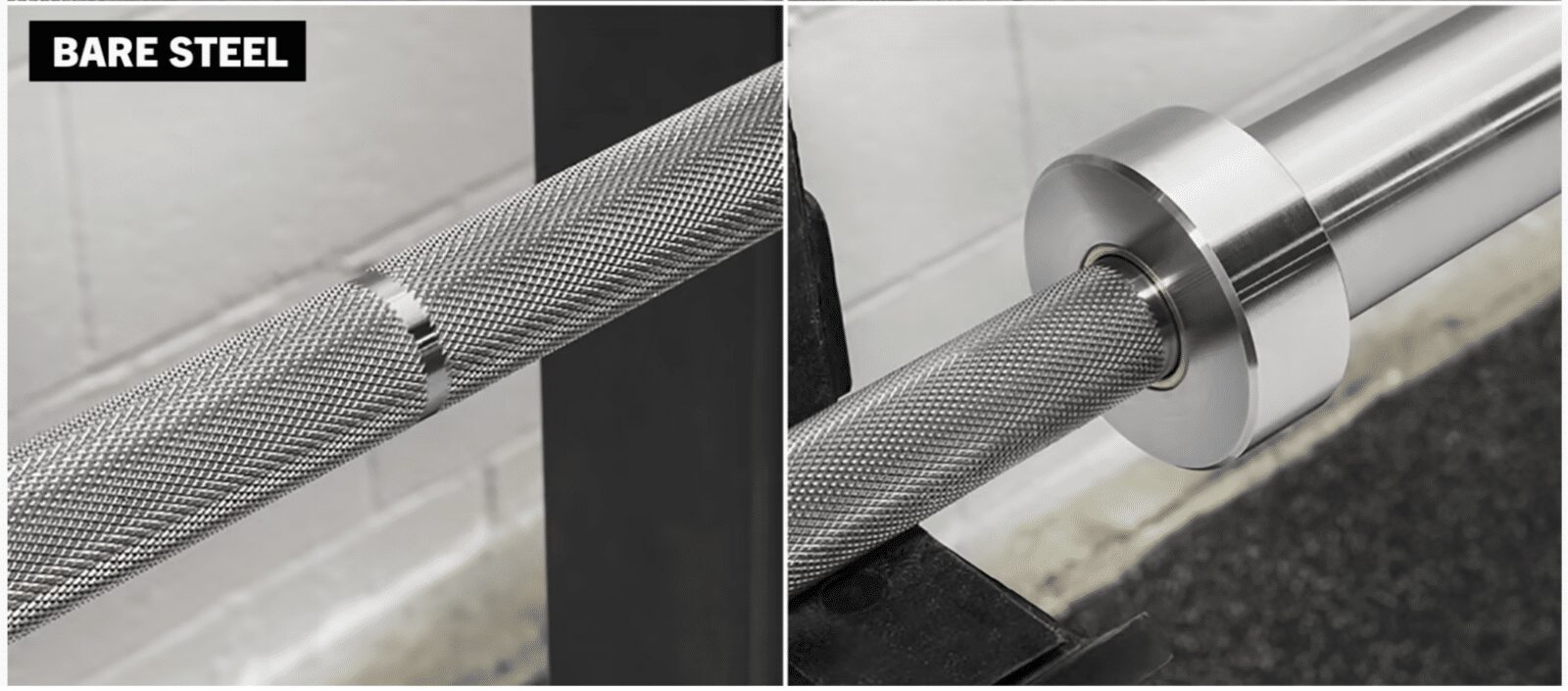

Bare Steel

Bare steel barbells, true to their name, lack any external coating, providing lifters with a raw and unaltered feel during their workouts.

This natural, untouched surface is highly favored by powerlifters and strength athletes who value a genuine grip and tactile feedback.

The absence of a protective coating on bare steel barbells, however, leaves them vulnerable to rust and corrosion.

Bare steel is inherently prone to oxidation, especially when exposed to moisture or humid environments.

As a result, regular maintenance becomes essential to prevent the onset of rust and maintain the barbell’s longevity.

This typically involves wiping down your bare steel bar with a clean cloth after each workout to remove sweat, moisture, and debris.

Applying a thin layer of corrosion-resistant oil or lubricant can provide an additional barrier against rust formation.

Humid environments pose a greater challenge for bare steel barbells as moisture levels are typically higher.

In such cases, it becomes crucial to monitor your bare steel barbell’s condition more closely and implement additional preventive measures.

These may include using a dehumidifier in the workout area, storing the barbell in a dry location when not in use, or applying a specialized rust inhibitor specifically designed for steel surfaces.

While bare steel barbells demand more maintenance compared to coated alternatives, many lifters appreciate the unique tactile experience they offer.

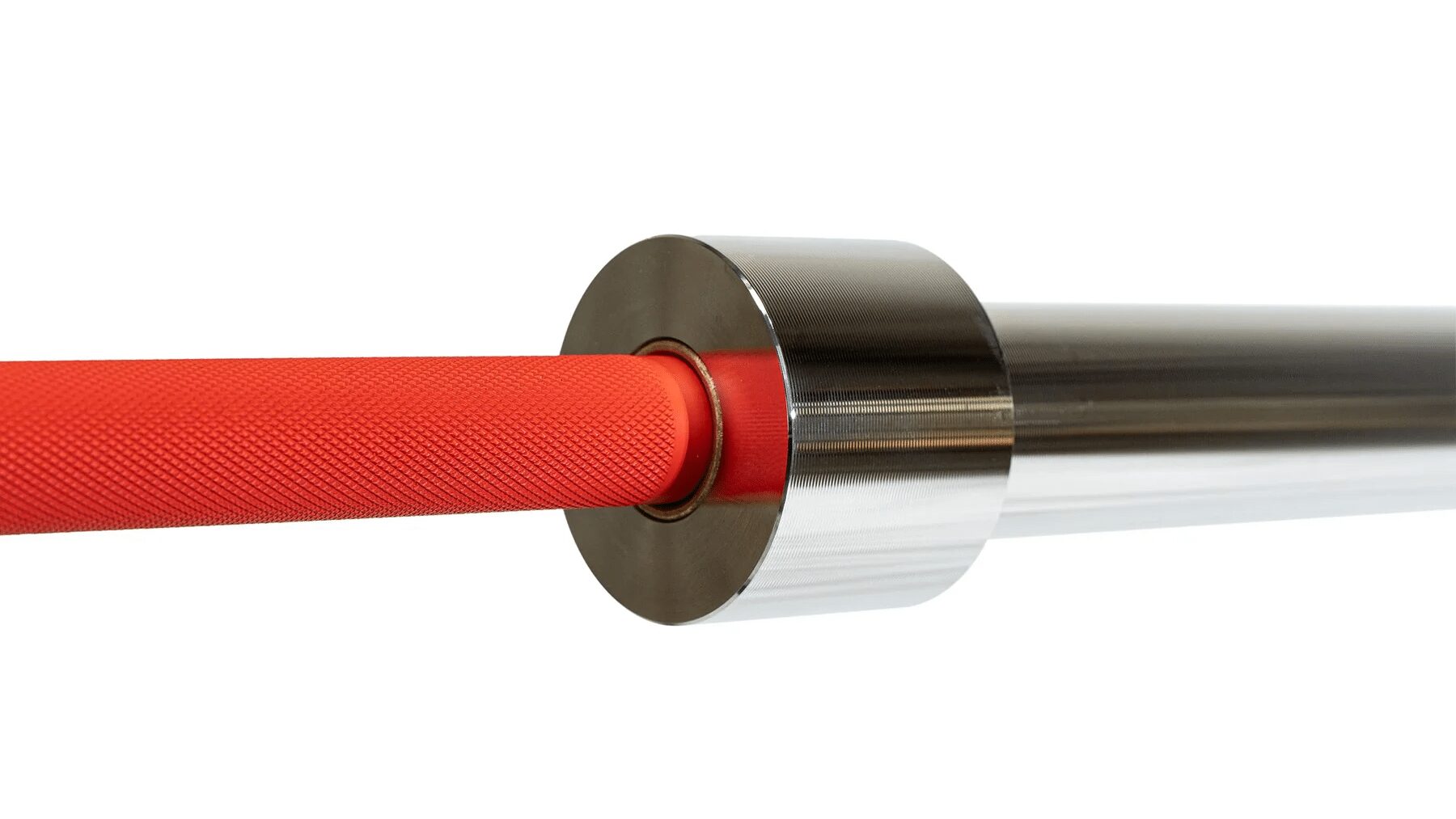

Cerakote

Cerakote is a ceramic-based coating that has gained immense popularity for its exceptional durability and extensive color options.

It has become the go-to choice for individuals seeking to personalize their barbells and add a touch of uniqueness to their training equipment.

Cerakote barbells are specifically engineered to withstand rigorous wear, corrosion, and exposure to chemicals commonly encountered during workouts.

This barbell finish provides robust protection, ensuring that your barbell maintains its aesthetic appeal and performance capabilities over time.

One of the standout features of Cerakote is the wide range of vibrant colors available.

This allows you to express your personality and style by selecting a barbell that resonates with your preferences.

Whether you prefer bold and vibrant hues or more subtle and refined tones, Cerakote offers an extensive palette to choose from.

While Cerakote offers numerous advantages, it is important to consider that it generally comes at a higher price point compared to other barbell coatings.

The added durability and customization options contribute to the increased cost.

Additionally, the Cerakote coating may have a slightly thicker feel compared to raw, bare steel, which may be a consideration for lifters who prefer a more tactile experience during their lifts.

Ultimately, the decision to choose Cerakote as a barbell coating comes down to your personal preferences, budget, and desired level of customization.

If durability, color options, and personalization are key factors for you, Cerakote can be an excellent choice to elevate your lifting experience.

E-Coat

E-Coat, also known as electro-coat, is a painting method that utilizes electrical current to evenly apply paint to the surface of a barbell, resulting in a uniform and durable coating.

This method is not only effective but also environmentally friendly, making it an appealing choice for eco-conscious individuals.

E-Coat barbells have excellent oxidation resistance, protecting the barbell from rust and oxidation over time.

The smooth and consistent finish achieved through the E-Coat process enhances the aesthetics of the barbell while maintaining its structural integrity.

One notable advantage of E-Coat barbells is their ease of maintenance compared to bare steel bars.

The protective coating helps mitigate the risk of rust formation, reducing the need for frequent maintenance routines.

However, it is important to note that E-Coat coatings may not offer as much grip as some other types of coatings.

When selecting a barbell coating, it is essential to evaluate your specific preferences and requirements.

If oxidation resistance, visual appeal, and low maintenance are key factors, E-Coat can be an excellent choice.

However, if grip is a primary concern, exploring other coating options that offer enhanced grip properties might better suit your lifting style and goals.

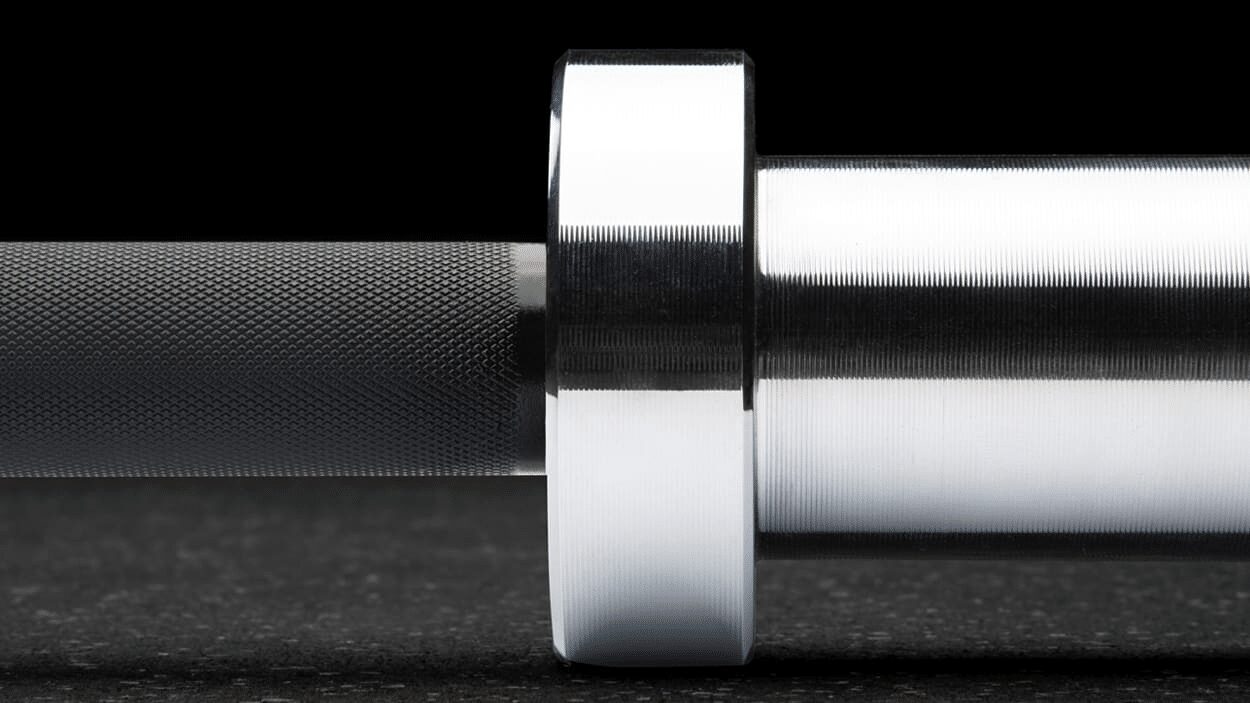

Hard Chrome

Hard chrome is a popular option for barbell coatings due to its impressive durability and resistance to wear.

Hard chrome barbells are known for their glossy appearance and exceptional strength, making them a reliable choice for heavy lifting.

One of the key advantages of hard chrome is its decent oxidation resistance, which helps protect the barbell from rust and other forms of deterioration.

The smooth feel of a hard chrome coating can be particularly beneficial for exercises like Olympic lifts, where a seamless and consistent grip is essential for optimal performance.

However, despite its durability, hard chrome coatings may chip or peel over time, especially with extensive use and heavy impact.

It’s important to note that this is a rare occurrence, but it’s worth considering when evaluating the longevity of the coating.

Additionally, it’s worth mentioning that hard chrome coatings may not provide as much grip as some other types of coatings.

This can be a factor to consider for specific lifts or for individuals who prefer a more textured grip on the barbell.

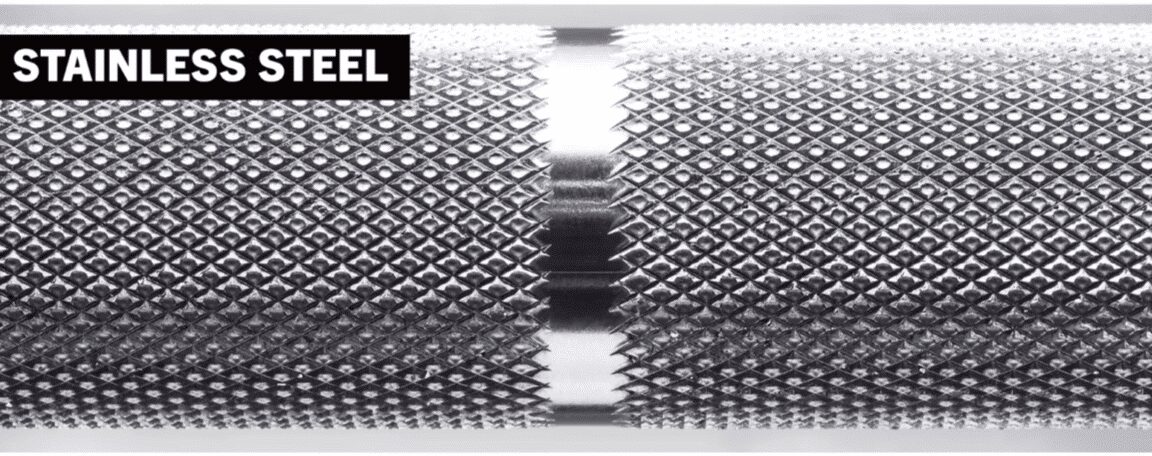

Stainless Steel

Stainless steel barbells are highly favored by fitness enthusiasts due to their exceptional oxidation resistance and natural feel.

If you’re searching for a barbell that demands minimal maintenance and can withstand humid environments, stainless steel is an excellent choice.

Renowned for its durability and resistance to rust, this barbell coating offers a raw and organic grip that many lifters find appealing.

The absence of a coating provides a direct connection to the bar, which feels amazing.

Stainless steel barbells can be a worthwhile investment for individuals seeking long-lasting performance and a genuine lifting experience.

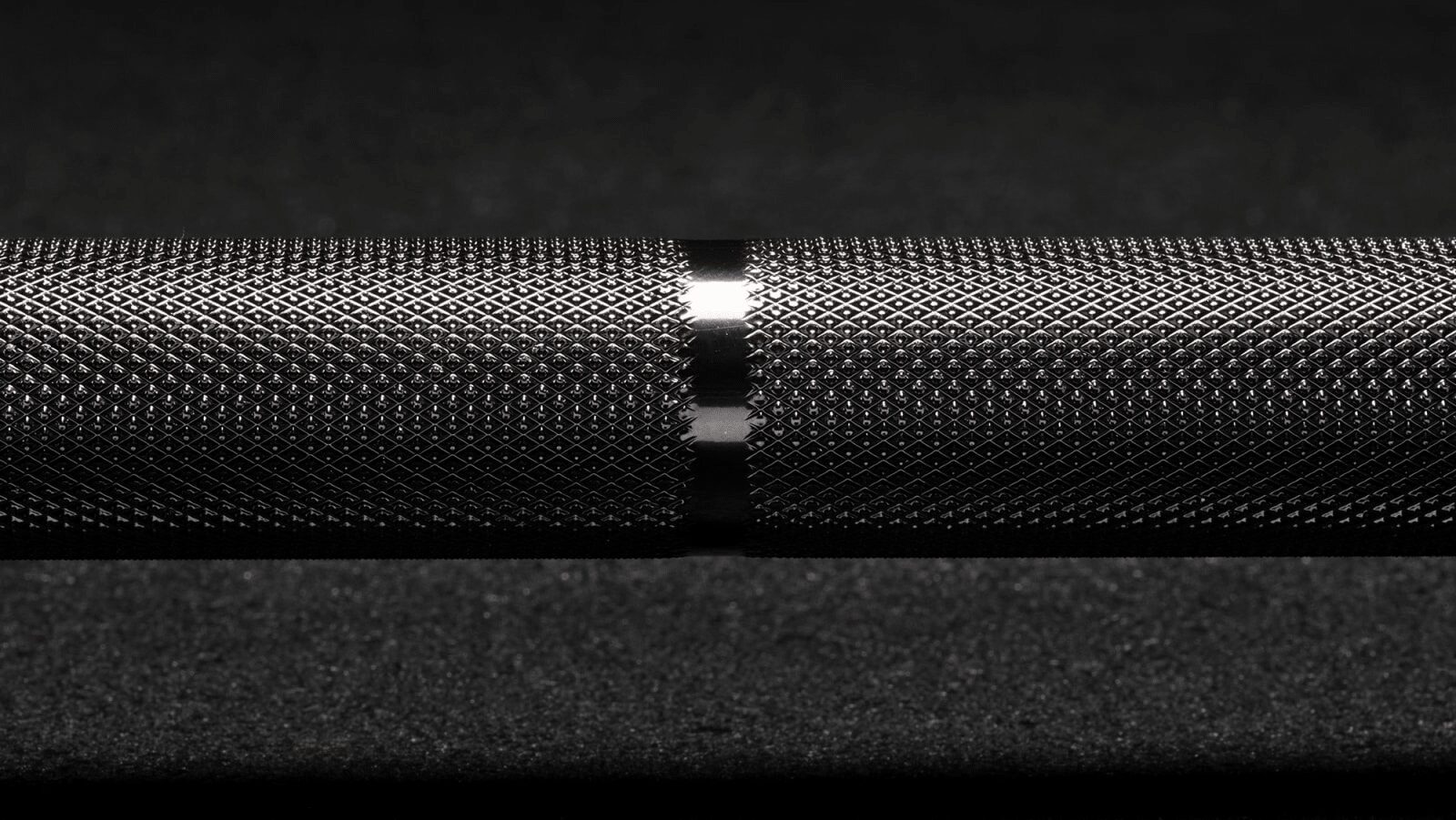

Zinc

Zinc coatings are commonly used for barbells and come in two main varieties: bright zinc and black zinc.

Both options offer a balance between durability, oxidation resistance, and cost-effectiveness.

Bright Zinc

Bright zinc barbell coatings provide a shiny, silver appearance to the barbell.

They offer good oxidation resistance and a reasonable grip.

Bright zinc-coated barbells are known for their affordability, making them a popular choice among budget-conscious lifters.

However, it’s important to note that this coating may wear off over time, particularly in areas of high contact or during heavy use.

Black Zinc

Black zinc coatings provide a darker, matte finish compared to brighter zinc finishes. They offer similar levels of durability and oxidation resistance.

These types of bars are also more affordable than stainless steel or Cerakote options.

This coating also provides an aesthetic appeal and can help reduce glare during workouts.

However, similar to bright zinc, the coating may gradually wear off with use, especially in high-contact areas.

When considering zinc-coated barbells, it’s essential to weigh the trade-off between cost, durability, and long-term maintenance.

Other Finishes

In addition to the barbell coatings mentioned above, there are a few other finishes you might come across.

Electroless Nickel – Electroless nickel is a type of coating that provides a uniform layer. It’s not as common as some other coatings, but it’s worth considering if you come across it.

Manganese Phosphate – Manganese phosphate is a type of coating often used on military equipment. It provides excellent oxidation resistance and a good level of grip.

Powder Coat – Powder coat is a type of coating that’s applied as a free-flowing, dry powder. It’s known for its high-quality finish and durability.

Factors Influencing the Choice of Barbell Coatings

When choosing a barbell coating, there are several factors to consider:

Aesthetics

For some people, the look of the barbell is an important factor.

Coatings like Cerakote come in a variety of colors, allowing you to customize the look of your barbell.

Here are the most common finishes and where they fit on the color hierarchy.

Colored Options – There can only be one, Cerakote!

Black – Black Oxide and Zinc, E-Coat, Powder coat

Silver – Bare steel, Bright zinc, Electroless nickel, Hard chrome, Stainless steel

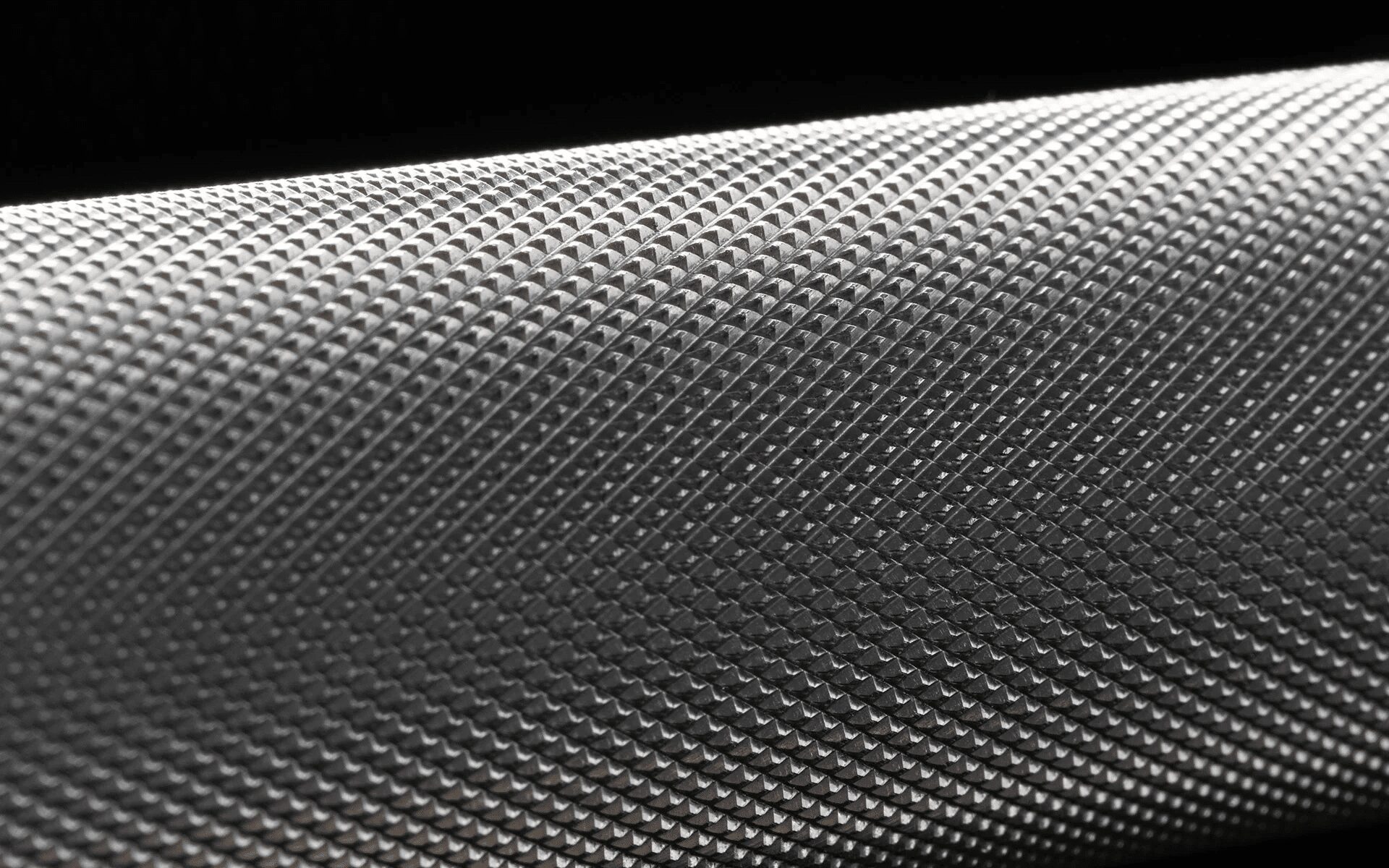

Feeling and Texture

The feel and texture of the barbell can significantly impact your lifting experience.

There are a couple of different barbell finishes that affect the feel of the knurling.

These are as follows:

Applied Coating – This type of coating is added to the barbell after it has been manufactured. The purpose of an applied coating is to provide a protective layer that can resist corrosion, enhance grip, and improve the barbell’s overall aesthetic. Common types of applied coatings include chrome, zinc, cerakote, e-coat, and powder coat.

Conversion Coating – This process involves a chemical reaction that converts the surface of the metal into a protective layer. The most common type of conversion coating for barbells is black oxide. Black oxide is a very thin coating that provides a moderate level of oxidation resistance. It doesn’t impact the feel of the bar much, which is why some lifters prefer it. However, it requires more maintenance than other coatings.

No Coating – Some barbells have no coating at all. These are often referred to as bare or raw steel barbells. While they offer the best feel and grip, they are prone to rust and require a lot of maintenance to keep them in good condition. Stainless steel barbells also fall into this category. Although stainless steel is more corrosion-resistant than bare steel, it’s not completely immune to rust but requires less maintenance.

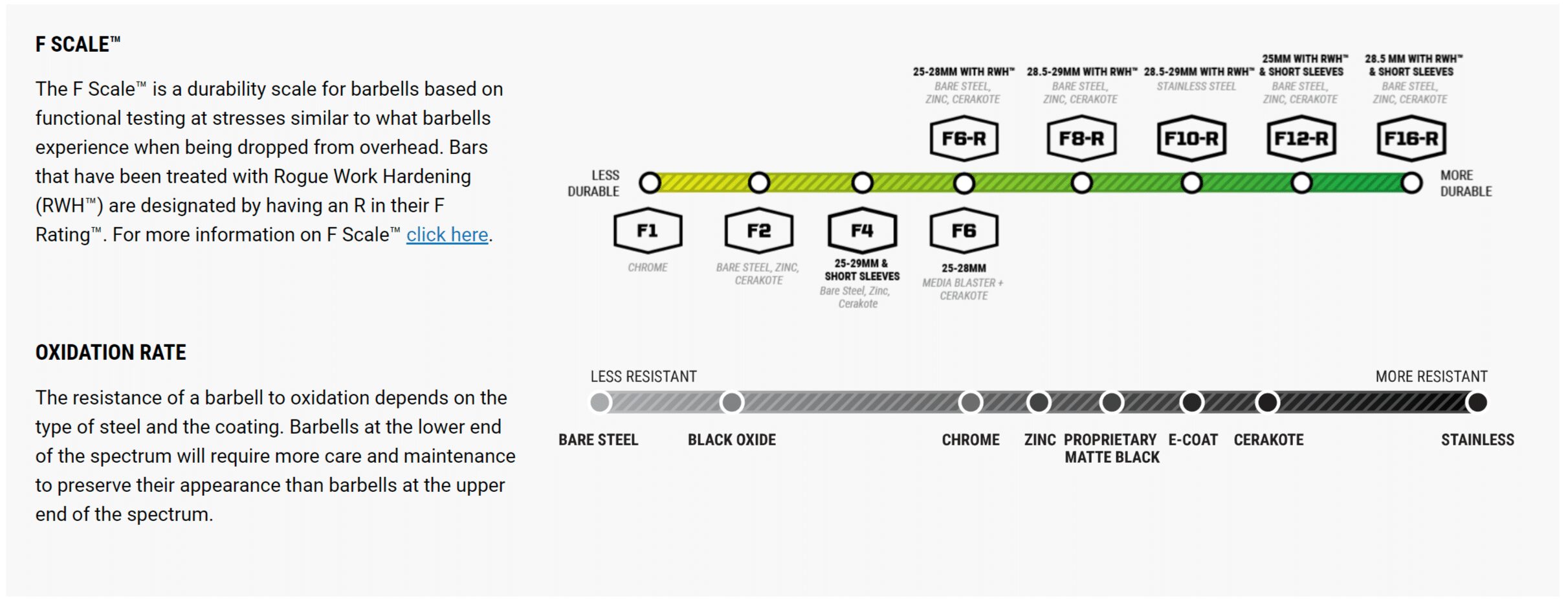

Oxidation Resistance

If you live in a humid environment or your gym doesn’t have climate control, you’ll want to choose a barbell with good oxidation resistance.

Here are the types of barbell coatings that provide the lowest amount of resistance to the highest.

Low Resistance – These coatings offer the least protection against rust, oxidation, and corrosion. They require more maintenance to keep the barbell in good condition.

Bare Steel – Bare steel barbells offer the best feel and grip, but they are the most prone to rust and require a lot of maintenance.

Black Oxide – Black oxide is a very thin coating that provides a moderate level of corrosion resistance. However, it requires more maintenance than other coatings.

Medium Resistance – These coatings offer a balance between feel and maintenance. They provide a good level of protection against rust, oxidation, and corrosion.

Zinc – Zinc coatings are corrosion-resistant and provide a good balance between feel and maintenance.

E-Coat – E-Coat (or Electrocoating) provides a uniform coating and is highly corrosion-resistant. However, it may not be as durable as some of the high resistance coatings.

Chrome – Hard chrome is a very durable and corrosion-resistant coating.

High Resistance – These coatings offer the highest level of protection against rust, oxidation, and corrosion. They require the least maintenance.

Cerakote – Cerakote is a type of ceramic coating that is highly durable and corrosion-resistant.

Electroless Nickel – Electroless nickel plating is a high-resistance coating that provides excellent corrosion and wear resistance. It’s also known for its uniform thickness over all surfaces, excellent hardness, and high resistance to wear.

Stainless Steel – Although stainless steel is not a coating, it’s worth mentioning here as it is more corrosion-resistant than bare steel and requires less maintenance.

Price

Finally, price is always a consideration. Some coatings, like stainless steel and Cerakote, are more expensive than others.

Be sure to balance the cost with the other factors that are important to you.

Here are some guidelines on how much each barbell finish costs.

Budget – Bare steel and powder coat

Value – Black oxide, E-coat, hard chrome, and zinc

Premium – Cerakote, Electroless nickel, and Stainless Steel

RELATED – How Much Does A Barbell Cost?

Maintenance of Barbell Coatings

Regardless of the type of coating you choose, proper maintenance is crucial to extend the life of your barbell.

Importance of Maintenance – Regular maintenance can prevent rust and wear, keeping your barbell in good condition for longer. It can also ensure a consistent feel and performance.

Maintenance Procedures for Different Coatings – Different coatings require different maintenance procedures

. For example, bare steel bars might need regular oiling to prevent rust, while other coatings might simply require regular cleaning with a nylon bristle brush.

Tools and Materials Needed for Maintenance – The tools and materials you’ll need for maintenance will depend on the type of coating. However, some common items include a nylon bristle brush, oil, and a clean cloth.

RELATED – The Essential Guide to Barbell Maintenance

Different Barbell Finishes Compared

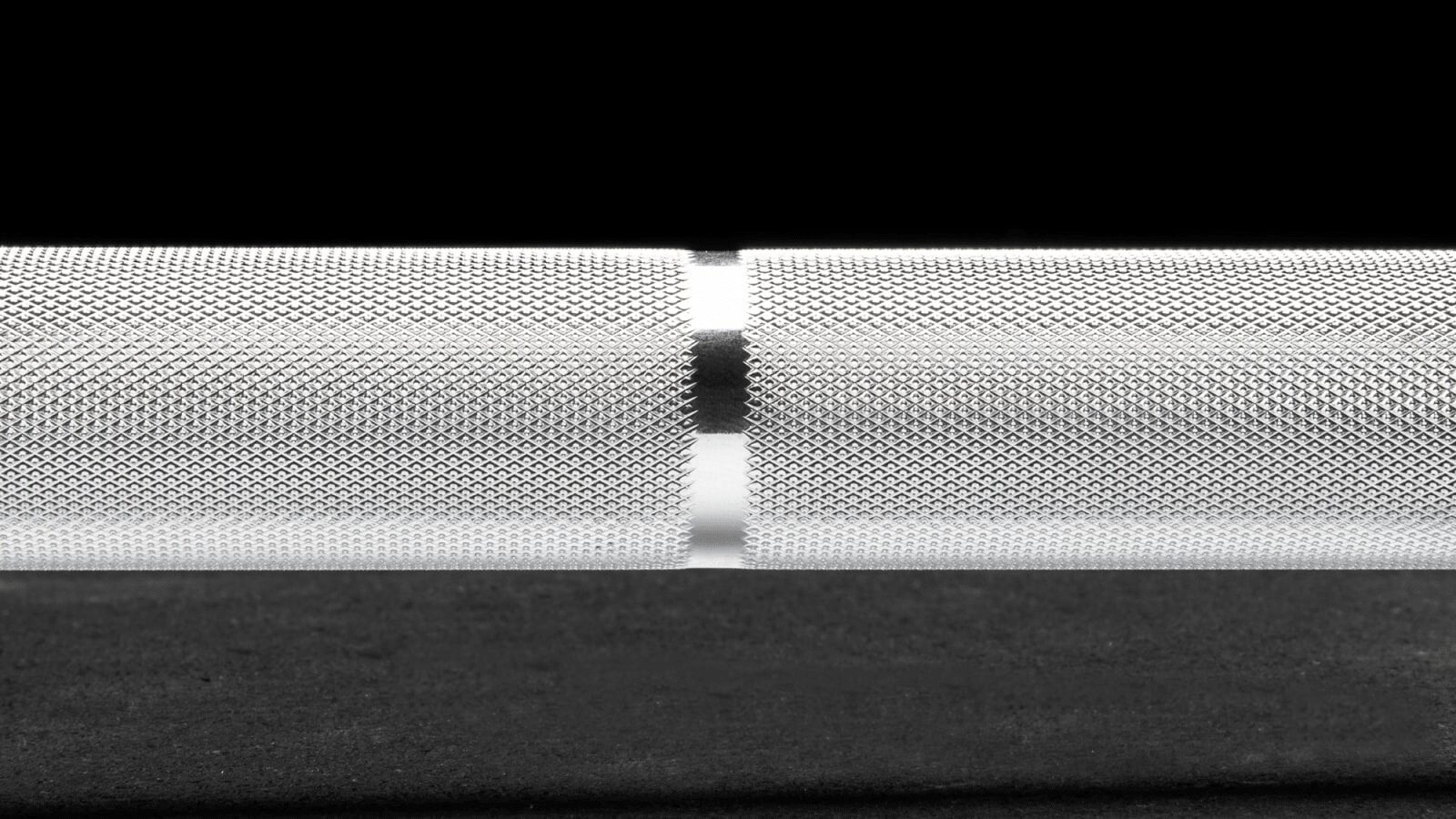

Bare Steel vs Stainless Steel

When it comes to the tactile experience, both bare steel and stainless steel barbells excel in providing an excellent grip.

Bare steel barbells, while offering a raw and authentic feel, do have a propensity for rust, necessitating consistent upkeep.

Stainless steel barbells, conversely, boast superior resistance to corrosion, reducing the frequency of maintenance.

Despite this, even stainless steel isn’t entirely immune to rust if neglected.

Black Oxide vs Black Zinc

In the realm of barbell coatings, these two finishes both hold their ground.

Black oxide, a conversion coating, imparts a decent level of rust resistance without compromising the bar’s natural feel.

Yet, it demands a higher degree of care compared to other coatings.

Black zinc, an applied coating, strikes a balance between rust resistance and tactile feel, making it a versatile choice.

Cerakote vs Stainless Steel

Cerakote, a ceramic-based coating, is renowned for its durability and ability to fend off corrosion.

It also provides a smooth feel and comes in a plethora of colors for a personalized touch.

Stainless steel, on the other hand, isn’t a coating but a material inherently more resistant to corrosion than bare steel, making it a low-maintenance option.

While both offer robust protection against rust, they differ in terms of tactile feel and aesthetics.

RELATED – Zinc vs Chrome Vs Cerakote vs Stainless Steel Barbell + Other Barbell Finishes!

E-Coat vs Black Zinc

These two bar coatings offer unique advantages.

E-Coat, known for its uniform application, provides high corrosion resistance.

However, its durability might not match up to some of the more resilient coatings.

Black Zinc, in contrast, offers robust rust resistance while maintaining a comfortable grip, making it a well-rounded choice.

E-Coat vs Cerakote

E-Coat and Cerakote, two prominent players in the barbell coating industry, each have their merits.

E-Coat is recognized for its uniform application and high resistance to corrosion, though it may fall short in durability compared to its counterparts.

Cerakote, a ceramic-based coating, is not only highly durable and corrosion-resistant but also offers a smooth feel and a wide color palette.

The decision between the two often hinges on individual preferences and specific requirements.

Frequently Asked Questions

Conclusion

Choosing the right barbell coating can enhance your lifting experience and extend the life of your barbell.

By considering factors like feel, oxidation resistance, aesthetics, and price, you can find the perfect barbell for your needs. And with proper maintenance, your barbell can last for many years to come.

Until next time,

-Dante

Related: